Using span tables to size joists and rafters is a straight-forward process when you understand the structural principles that govern their use.

by Paul Fisette

© 1997

Wood is naturally engineered to serve as a structural material: The stem of a tree is fastened to the earth at its base (foundation), supports the weight of its branches (column) and bends as it is loaded by the wind (cantilever beam). A complete analysis of wood’s mechanical properties is complex, but understanding a few basics of lumber strength will allow you to size joists and rafters with the use of span tables.

Let’s start by taking a broad view. The structural goal of a house is to safely transfer building loads (weights) through the foundation to the supporting soil. Remember when your science teacher said: every action has an opposite and equal reaction? Well every building load has an equal “reaction load”. If, when the loads of the house are combined, the house weighs more than the soil can support – the house will sink until it reaches a point at which the soil can support the load. This article will focus on how simple beams like joists and rafters react to loading.

Residential Loading

The house acts as a structural system resisting dead loads (weight of materials), live loads (weights imposed by use and occupancy), like snow loads and wind loads. Beams, studs, joists and rafters act as a structural skeleton and must be strong enough and stiff enough to resist these loads.

Strength and stiffness are equally important. For example, first-floor ceiling plaster would crack as occupants walked across a second-floor bedroom that was framed with bouncy floor joists. Perhaps the joists were strong enough if they didn’t break! But lack of stiffness leads to costly problems.

Stiffness of structural members is limited by maximum allowable deflection. In other words, how much a joist or rafter bends under the maximum expected load. Only live loads are used to calculate design values for stiffness.

Maximum deflection limits are set by building codes. They are expressed as a fraction; clear span in inches (L) over a given number. For example: a floor joist appropriately selected to span 10 feet with an L/360 limit will deflect no more than 120″/360 = 1/3 inches under maximum design loads. Drywall attached to the underside of this system is not expected to crack when the floor joist system deflects 1/3″.

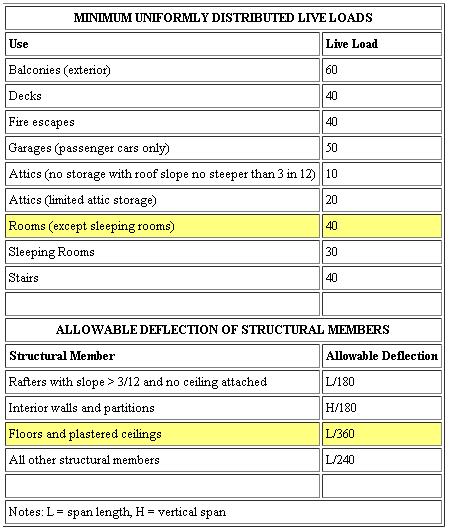

Typical deflection limits referenced in code books are L/360, L/240 or L/180. These limits are based on live loads and activities experienced in specific rooms of a house. Examples of code-prescribed deflection limits and live load values are:

- Living room floors L/360 & 40 psf

- Bedrooms and habitable attic floors L/360 & 30 psf

- Attic floors with limited storage L/240 & 10 psf

Strength of a material is obviously important. Joists, and rafters must be strong enough not to break when loaded. Unlike stiffness, live loads and dead loads are added together to determine minimum design values for strength.

To determine the dead load value for a given floor or roof system, the weight of all permanently installed materials in a given component are added together. For a floor system you can find the individual weights of drywall, strapping, floor joists, subfloor, underlayment and carpet in an architectural handbook like Architectural Graphic Standards. But for most cases there is a cookbook solution. Simply reference Span Tables for Joists and Rafters published by the American Wood Council (AWC). AWC’s Appendix A lists a variety of live and dead load combinations for floors, ceilings and rafters. For example, Appendix A indicates that one type of clay tile roof system has a live load value of 20 psf and a dead load value of 15 psf.

Factors That Influence

Many factors influence how a system responds to loading. It is important to realize that the way you select and use materials will control costs and performance.

- Depth of structural members. Often, 2×10 joists spaced 24-inches o.c. will provide a stronger and stiffer floor assembly than 2×8 joists of the same grade and species that are spaced 16-inches o.c.

- E value or modulus of elasticity of the individual elements. E is a ratio that relates the amount a given load causes a material to deform. A material with a higher E value is stiffer. For example: No.2 grade eastern white pine has an E value of 1,100,000 and No.2 hem-fir has an E value of 1,300,000. Hem-fir is a stiffer material.

- Fb value or extreme fiber stress in bending. Loads cause beams, joists and rafters to bend. As a beam bends the outermost (extreme) fibers are compressed along the top edge. And at the same time, fibers stretch along the bottom edge. The outermost (extreme) wood fibers on the top and bottom surfaces are stressed more than those fibers in the middle. An Fb value indicates design strength for those extreme fibers. The higher the Fb the stronger the wood.

- Lumber grade. A higher grade of a given species has a higher strength rating (Fb) and often has a higher stiffness value (E) too.

- Species of wood. All species are not created equal. For example southern pine is much stronger and stiffer than spruce.

- Duration of load. How long will the members be loaded? Full-time loading (floor joists) serves as the benchmark value. Benchmark values are multiplied by 1.15 to yield snow-load values and by 1.25 for 7-day loading. Don’t worry about the calculations! Tables automatically handle this adjustment. You just read the numbers under the appropriate column heading. For example: A select structural, southern pine 2×8 floor joist has a 2650 Fb. While the same grade and species 2×8 has a 3040 Fb when used as a roof rafter in snow country. E values are unaffected by duration of load.

What You Need

Alright, so now you want to use this information. First you need to get a few things: Code book; AWC’s Span Tables for Joists and Rafters (this assigns allowable spans to various combinations of E and Fb); and a copy of Design Values for Joists and Rafters (this has Fb and E values for various species, sizes and grades of dimension lumber).

The code book can be purchased through your local code official. Building codes provide you with information about required grades, spans, bearing, lateral support, notching, etc. Purchase ICC’s .

These documents provide an expanded view of span-table use through “explanation” and “commentary” sections at the beginning and end of the publications. I find the AWC documents easy to follow. The technical staff at AWC is eager and able to help you understand the documents if you get stuck. You can contact the AWC Help desk at 1-202-463-4713 or via email at info@awc.org.

There are other span tables and publications available too. The following are links to several online span tables:

- Canadian Wood Council Span Calculator

- Southern Forest Products Association Span Tables

- Western Wood Products Association Span Tables

Pulling It All Together

Calculating Loads

For the most part, live load and dead load values for floor and roof systems are considered distributed loads. In other words, the weight is distributed or shared uniformly by the members in the floor or roof system. In order to establish proper sizes, grades and on-center spacing of joists and rafters you first need to determine what loading is acceptable to the building code.

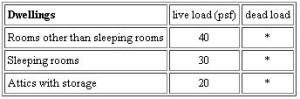

Use your code book here. Look up the allowable loads and deflection limits imposed by your local code. For example: the International Residential Code includes the following information.

Floors & Ceilings (joists)

Deflection

The code section on allowable deflection of structural members indicates that the deflection shall not be greater than L/360 for floors and plastered construction; L/180 for rafters having slopes greater than 3/12 with no finished ceiling attached to rafters; and L/240 for all other structural members. So these are the limits set by the code.

You can also use AWC’s Span Tables for Joists and Rafters. This is the easiest way to determine allowable dead loads, live loads and deflection limits. This publication has a much more extensive offering of possible joist and rafter conditions.

Once you find the appropriate table in the book, you determine acceptable Fb and E values for your particular span condition. Span is the distance from face to face of the supports. (for joists: from basement-side of sill to sill-side of center girder.)

Rafters

Rafters are sized the same way as joists: Establish live load, dead load and deflection limits; use the appropriate rafter table to determine acceptable Fb and E values; and then select the appropriate species, size and grade from AWC’s Design Values for Joists and Rafters publication.

Sizing rafters differs from sizing joists in 2 ways:

- The span of a rafter is not based on the measurement along its length. Rather, the span is based on the rafter’s “horizontal projection”. This is the horizontal distance from the inside surface of the supporting wall to the inside surface of the ridge board. So consider a simple gable roof on a 24-foot wide ranch framed with 2×6 exterior walls and a 1 1/2 ridge: the span would be 11’5 3/4″.

- You must determine the snow load for your region. This information is found in the code book. The snow load is treated as a live load when you use AWC’s tables. If your code book says your snow load is 40 psf, then you use the 40 psf live load rafter table. The fact that snow loads only act part of the year has been used to create the rafter tables.

Compression Perpendicular to the Grain

The loads carried by floor joists, ceiling joists and rafters are transferred through their end points to supporting walls and beams. The ends of these members must be able to “react” or resist these loads without crushing. AWC lists the required compression perpendicular to grain values for joists and rafters for various spans, on-center spacing and loading conditions in its Span Tables for Joists and Rafters. AWC’s Design Values for Joists and Rafters lists compression perpendicular to grain design values for a variety of species. Just be sure the species design value exceeds the required compression perpendicular to grain value for your structural condition.

Summary

Step By Step

Here is a checklist of steps to follow when using span tables

- Check plans to determine span and on-center spacing (design conditions)

- Check codes for allowable live load, snow load, dead load and deflection

- Select appropriate span table

- Match span in table to design condition and determine minimum Fb and E values listed in the span table

NOTE: you will have options for on-center spacing and size - Select appropriate species and grade from values listed in design values table

NOTE: you will have options regarding species and grade providing you with an economic opportunity - Determine required compression perpendicular to grain design value in table

- Verify that the compression perpendicular to grain design value for the species selected in step 5 meets the required design value determined in step 6

Example: A Test Case

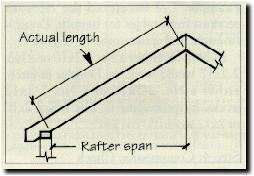

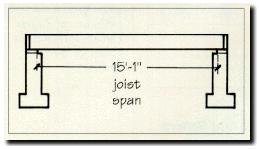

Test your skill. Let’s work through an example that illustrates the steps involved in using the tables. Let’s say you’re building a 16-foot addition and have to select the correct size and species of lumber for the floor joists. The joists will be 16 inches on-center. Their design span, the exact length from face to face of the supports, is 15 feet 1 inch (see illustration – Figure 1)

Figure 1

When sizing joists, use the clear span – the length from support to support – not the full length of the joist.

Steps

Floor Joists

Step 1 Check The Code: First check the local code for allowable live load, dead load, and deflection (see Figure #2). For this example, I’ll use the ICC , which serves as the model for many state and local codes. This sets an allowable first-floor live load of 40 psf, a dead load of 10 psf, and a deflection of L/360.

Figure 2

Live loads and deflection limits are set by code. These tables are from the ICC International Residential Code.

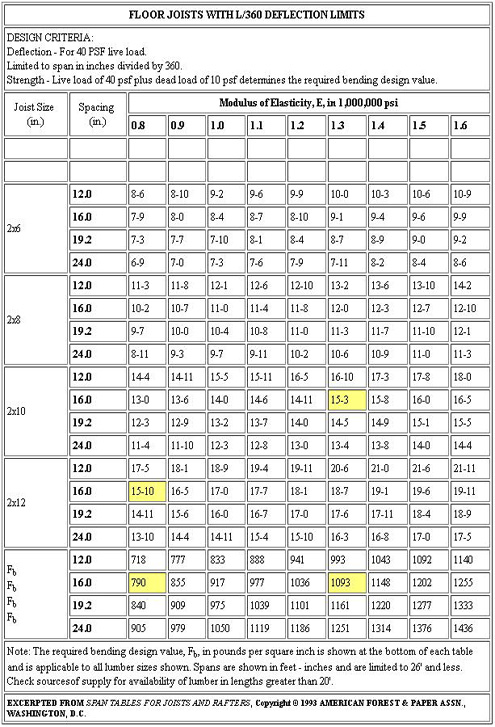

Step 2 Span Table: Select the appropriate table in Span Tables for Joists and Rafters. The Table of contents indicates that Table F-2 matches these loading conditions. Using Table F-2 (Figure #3), check each lumber size to see if a 16-inch spacing will permit a span of 15 feet 1 inch. Start with the “16.0” line in the “Spacing” column at the left of the table, then go to the right until you reach an appropriate span at least 15 feet 1 inch in this case). Then drop down to find the appropriate Fb value for the span.

As the table shows, no 2×8’s meet the span and spacing requirements, but a 2×10 with an E of 1,300,000 psi and Fb of 1093 psi can span 15 feet 3 inches – more than enough. A 2×12 with an E of 800,000 psi and Fb of 790 psi also works, since it can span 15 feet and 10 inches.

Figure 3

Given a design span of 15 feet 1 inch and a 16 inch joist spacing, first determine which size lumber will work. Then find the required Fb value at the bottom of the column.

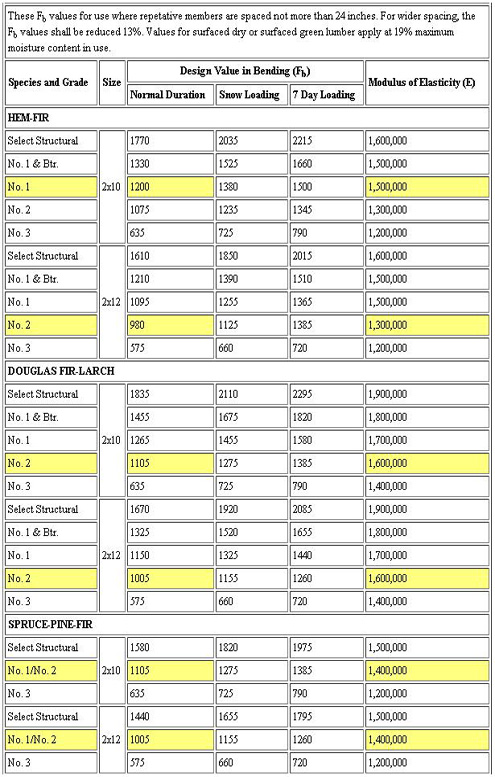

Step 3 Wood Design Values: Now you must select a wood species and grade that meets the required Fb and E values, and that’s available in your area. For this, use the tables in Design Values for Joists and Rafters. For this example, I’ve excerpted the relevant sections from tables for hem-fir, Douglas fir-larch, and spruce-pine-fir (Figure 4). In hem-fir, either a No.1 2×10 or a No. 2 2×12 would work. In Douglas fir-larch, either a No. 2 2×10 or a No. 2 2×12 works. In spruce-pine-fir, No. 1/No. 2 2×10 or 2×12 would do the job.

Figure 4

After determining what size lumber to use, turn to the tables in Design Values For Joists and Rafters to select a species and grade that meets the required Fb and E values. The tables shown here are excerpts from the hem-fir, Douglas fir-larch, and spruce-pine-fir tables.

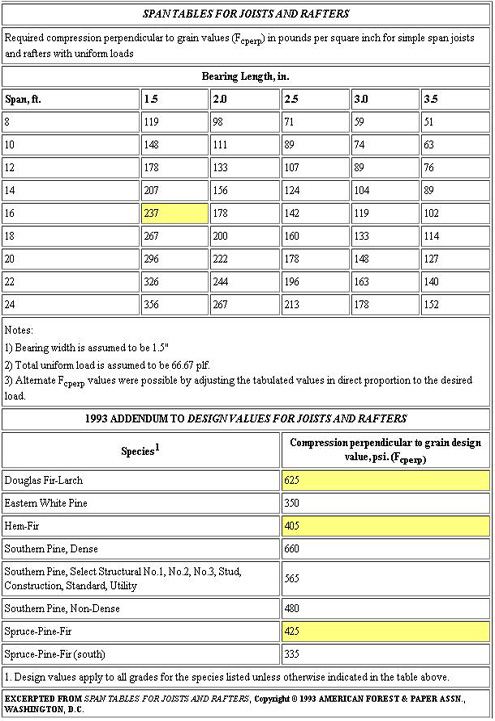

Step 4 Bearing Check: The final step is to make sure the lumber you’ve chosen meets the required design value for compression perpendicular to the grain. The loads carried by floor joists, ceiling joists, and rafters are transferred through their end points to supporting walls and beams. The ends of these members must be able to resist these loads without crushing.

Table 9.1 in Span Tables for Joists and Rafters (Figure 5) gives a required compression value of 237 psi for a span of 16 feet and bearing length of 1.5 inches. (the tables permit a bearing length of up to 3.5 inches, but since 1.5 is probably the worst case that you’ll encounter for joist or rafter bearing, it’s a safe value.) You can get the compression perpendicular to grain design value for various species selected from the addendum that comes with Design Values for Joists and Rafters. For instance, hem-fir has an acceptable value of 405 psi, spruce-pine-fir of 425 psi.

Figure 5

Check to see that the lumber species selected has the necessary compression strength perpendicular to the grain. This table, from Span Tables for Joists and Rafters, gives the required values for various design conditions; an addendum that comes with Design Values for Joists and Rafters gives the valies for specific species.

Ceiling Joists and Rafters

Ceiling joists are sized like floor joists except that deflection limits vary depending on whether the joists will be used for attic storage or will have a plaster or drywall finish. Check your code and follow the AWC tables accordingly.

When using the tables to size rafters, there are two points to keep in mind. First, remember that the rafter’s span is not its actual length, but its total horizontal projection (see Figure 6). Second, use the snow load value for your region in determining which rafter table to use. If your code book says your snow load is 40 psf, then you must use the 40 psf live load rafter table. The fact that snow loads only act part of the year has been taken into account in the rafter tables, but don’t forget to use the “Snow Loading” column to get the Fb design value.

Figure 6

Use the horizontal projection of a rafter, not its actual length, when figuring rafter span