Fastener Corrosion

Background

Starting January 1, 2004, Chromated Copper Arsenate (CCA) treated wood products were no longer permitted to be manufactured for general sale, with only some minor exceptions for use in limited, well-defined applications. (See https://www.epa.gov/ingredients-used-pesticide-products/chromated-arsenicals-cca

for more information.). Some of the commonly available preservative-treated wood products will be treated with ammoniacal copper quat (ACQ), copper azole (CBA/CA-B), or ammoniacal copper zinc arsenate (ACZA). While these alternative treating chemicals have been proven to be effective wood preservatives when used in accordance with AWPA standards, there is some evidence that these chemicals are more corrosive than CCA to metal fasteners and connectors.

The purpose of this document is to provide answers to some specific questions related to this issue. Users are cautioned that this information is only a synthesis of reports currently available from public sources. A number of sources are attempting to assess the corrosivity of treatment chemicals. Updates will be issued as new or additional information becomes available.

Questions and Answers

Q: Lumber treated with CCA has been available for many years. Does metal corrode in contact with CCA-treated lumber?

The chemicals used in CCA-treated lumber have been shown to be somewhat corrosive to fasteners and connectors. Accordingly, chemical manufacturers and the treated lumber industry have traditionally recommended and the model building codes have required the use of corrosion-resistant fasteners and connectors when used with CCA-treated lumber.

Q: What’s different with the new alternative treatments?

When subjected to standardized laboratory tests that accelerate the corrosion process, metal connectors and fasteners exposed to the chemicals used in ACQ, Copper Azole, or ACZA exhibit higher rates of corrosion than connectors and fasteners exposed to CCA. Discussions within the affected industries are attempting to sort out the significance of these differences in real-world applications.

Q: What should users do while the technical issues are being evaluated?

At the very least, users should rigorously apply the recommendations of the chemical manufacturers and the treating industry—to use corrosion-resistant fasteners and connectors or zinccoated (galvanized) fasteners and connectors with corrosion protection at least equivalent to that of hot-dip galvanized products.

Q: What zinc coating specifications apply to hot-dip galvanized products used in wood building construction?

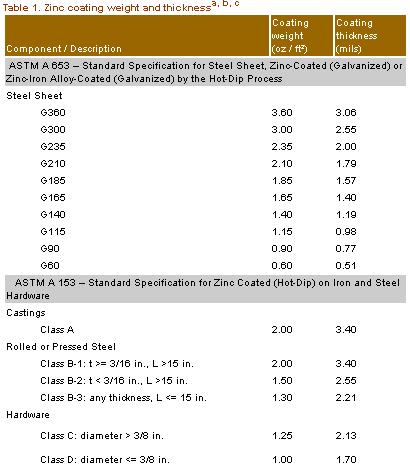

Specifications for sheet metal connectors (joist hangers and metal straps) and fasteners (such as nails and bolts) are addressed in separate ASTM standards. Coating weight designations for sheet steel are specified in ASTM A 653, Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process. An example zinc coating designation in ASTM A 653 is G185 where “G” indicates zinc coating and “185” indicates a total of 1.85 oz/ft2 of coating on both sides of the steel sheet. For fasteners, minimum coating weights are specified in ASTM A 153, Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware. A Class D designation applies for fasteners 3/8” in diameter and smaller. The minimum coating weight associated with Class D is 1.0 oz/ft2.

Q: Is there a difference between “hot-dip” galvanized products and other types of galvanized products manufactured using a different process?

There are a variety of processes for galvanizing metal products other than the hot-dip process. These include electrolysis (electrogalvanized, zinc plated) and peening (mechanical plating). There are some differences and issues that users should be aware of:

Coating thicknesses developed by the electrolysis process may be too thin. Most commonly available electrogalvanized or zinc-plated fasteners and connectors do not have a sufficient coating of zinc for these new chemicals.

The density of the coating can be less than provided by the hot-dip process. For example, mechanically deposited coating in accordance with ASTM B 695 Standard Specification for Coatings of Zinc Mechanically Deposited on Iron and Steel has a density that is approximately 75% of the density of the zinc coating resulting from the hot-dip process. Approximately 33% greater coating thickness is needed to produce the same level of zinc per unit area as provided by the hot-dip process.

Q: What connectors provide maximum corrosion resistance?

Type 304 and 316 stainless steel have been used to provide maximum corrosion resistance. Type 304 and 316 stainless steel connectors and fasteners have been used in demanding applications such as coastal exposures and in permanent wood foundations.

Q: What other details should users and specifiers be aware of?

There are other issues that have been reported that are important to users:

Never mix galvanized steel with stainless steel in the same connection. When these dissimilar metals are in physical contact with each other, galvanic action will increase the corrosion rate of the galvanized part (the zinc will migrate off the galvanized part onto the stainless part at a faster rate).

Galvanizing provides a sacrificial layer to protect the steel connector or fastener. Greater thicknesses (coating weights—see Table 1) generally provide longer protection in corrosive environments.

Aluminum should not be used in direct contact with CCA, ACQ, Copper Azole, or ACZA.

Q: Are all alternative treatments more corrosive than CCA?

The majority of the research has been conducted on the corrosivity of ACQ and Copper Azole. Comparative testing has indicated that borates are less corrosive but users should still consult manufacturer recommendations regarding corrosion-resistant fasteners or corrosion protection of fasteners and suitable applications for borate treatments.

More Information

A search on the internet will provide a long list of “hits” on this topic. Information on the following web sites may be especially useful to users of treated wood products:

General:

The Federal Emergency Management Agency (FEMA) provides recommendations for fasteners and connectors used in coastal areas – Technical Bulletin 8-96 Corrosion Protection for Metal Connectors in Coastal Areas.

The American Galvanizers Association (AGA) provides information types of zinc coatings and characteristics of zinc coatings – Zinc Coating

Additional Resources and Information is Available From: