Pitch Chord Trusses

In a roof truss, the three sides (or perimeter elements) of the triangle are called chords. The webs are wood pieces connecting the top and bottom chords. Chords and webs are the members or elements of the truss. The connectors joining chords and webs in modern trusses are usually metal-toothed plates. Metal-plate-connected wood trusses were introduced in the mid-1950s. The most common application is in the roof assembly. Trusses used to form the roof assembly are referred to as pitch chord, since the top chord is sloped. The bottom chord is typically horizontal, since it directly supports the ceiling. Complex roof structures can be assembled and sheathed using factory-supplied trusses.

Pitched chord roof trusses are tightly banded for shipment and storage on the job.

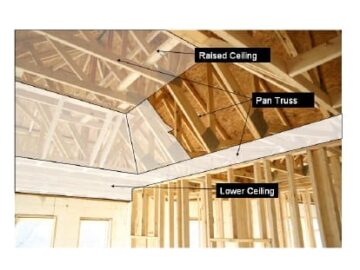

Pitched chord truss bottom chords can be configured to create a raised ceiling.

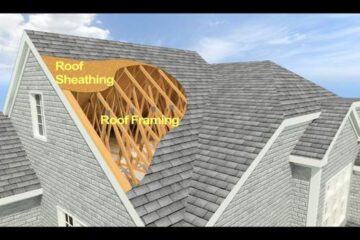

This roof cutaway drawing reveals the trusses beneath the wood structural panel roof sheathing.

Ductwork for indoor heating and cooling rests on the bottom chord of steep pitch chord roof trusses.

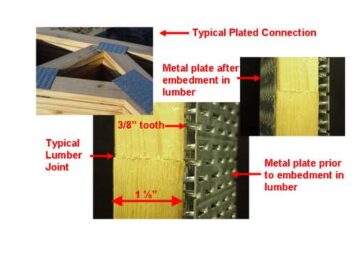

Metal plate connectors are used to join truss chord and web members. The plates are embedded using hydraulic presses.

A structural frame is used to load a pitch chord truss for research purposes.

The bottom chord of pitch chord trusses can be fabricated to create unique interior spaces, such as this pan ceiling effect.

A pitched chord truss supporting a "bonus room" above a garage. The bottom chord is fabricated from a wide EWP, since it serves also as a floor joist for a narrow room accessible from the second floor hallway.

A simple pitch chord truss.

Metal plate connectors are engineered for each loading condition. They are embedded into the wood fiber using hydraulic presses to ensure the teeth penetrate the fiber.

Metal connector plates are sized and positioned at each joint to ensure the correct number of teeth penetrate each wood member.

Pitch chord trusses can be manufactured with raised heels at the bearing point on exterior walls. This allows for the placement of insulation, while maintaining code-required attic ventilations.

Raised heel pitched chord trusses bear on double top plates and are connected to the wall with metal straps to resist wind uplift forces.

Pitched chord roof trusses are lifted into place by a crane and will be placed along the top plate by the carpenters.

The few remaining pitch chord roof trusses are lifted into place over the garage.

Hydraulic presses are used to embed the metal connectors into the wood fiber of this pitched chord roof truss.

Pitched chord roof trusses are attached to the wall top plate and header with metal connectors.